Supply Planning

Build and position the right inventory at the right place

With shorter product life cycles, new competitors and expanding partner-supplier networks, organizations like yours need to be able to sense, process, plan and respond to changes in real-time. Blue Yonder supply planning capabilities help you stage the right inventory throughout your distribution network, minimizing stock-outs while maximizing inventory turns in your supply chain. Discover how you can gain a strong return on your invested capital and minimize inventory while maintaining the high level of service your customers expect.

A Leader in the 2024 Gartner Magic Quadrant

for Supply Chain Planning Solutions

Download a copy of the report and learn why Blue Yonder's Supply Chain Planning Solutions have been recognized for excellence.

10%

Reduced Inventory

20%

Improved Productivity

30%

Reduced Expenses

Achieve More Optimized Supply Chains with Blue Yonder

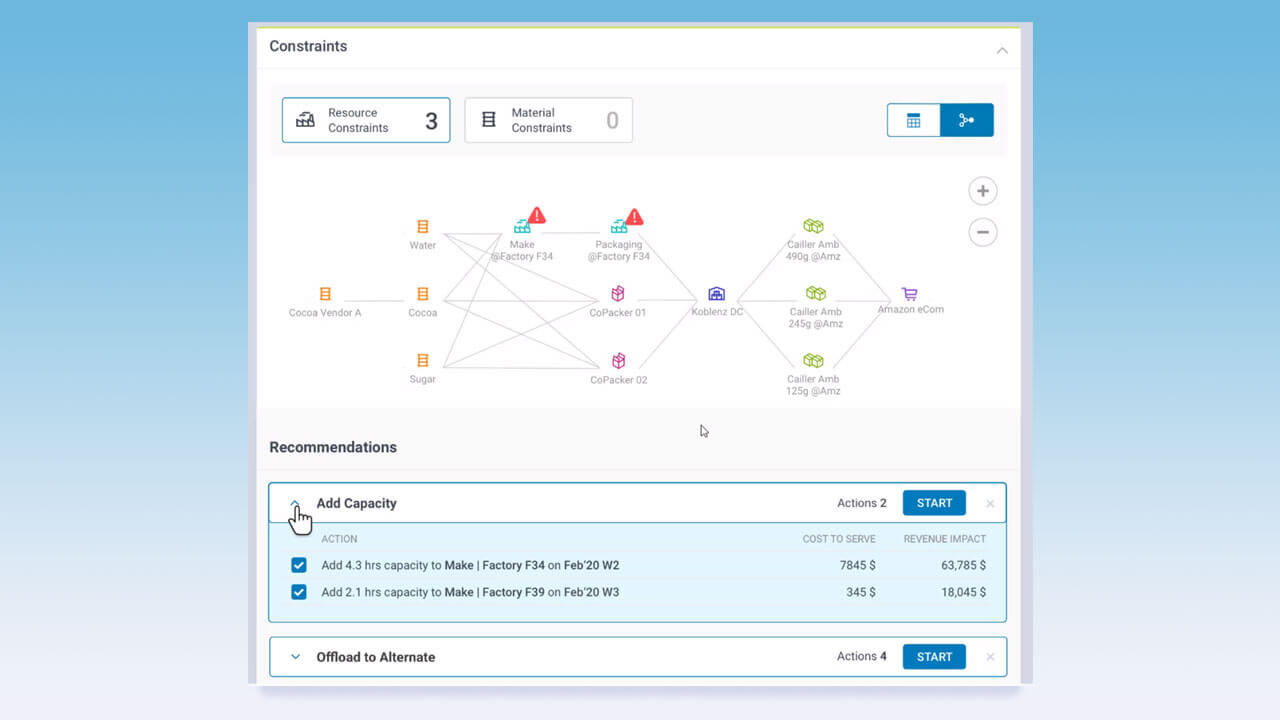

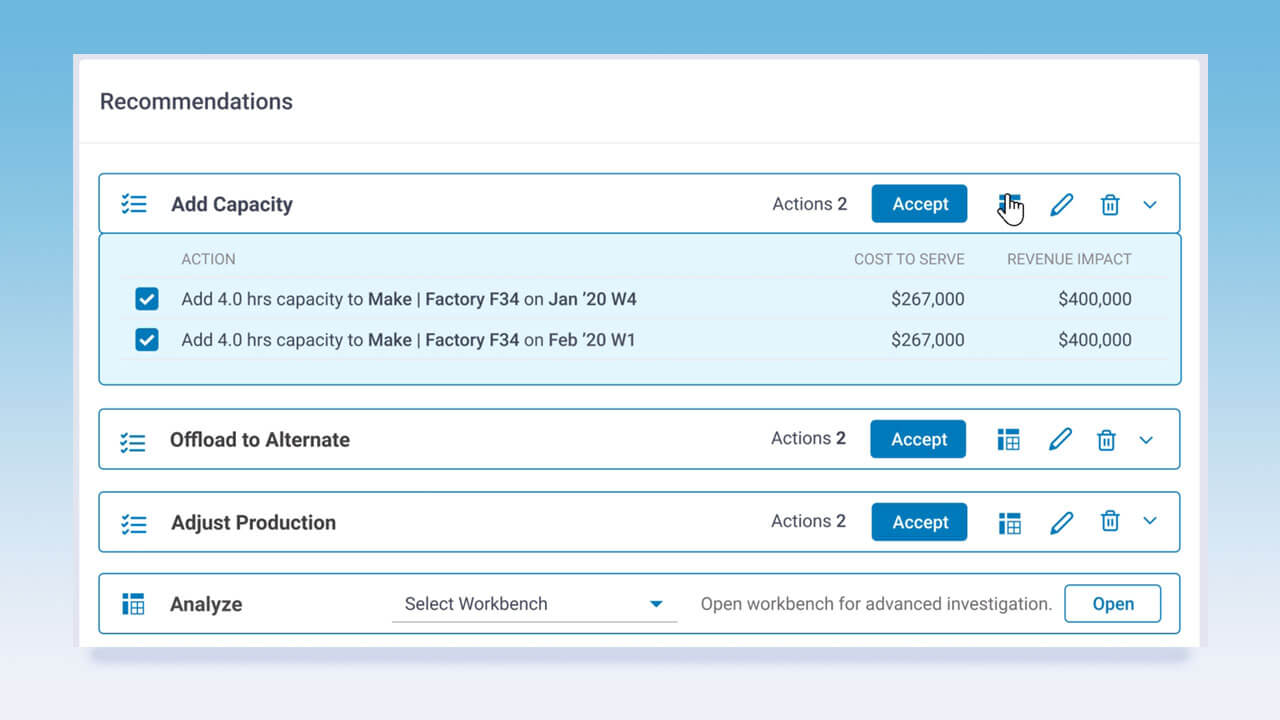

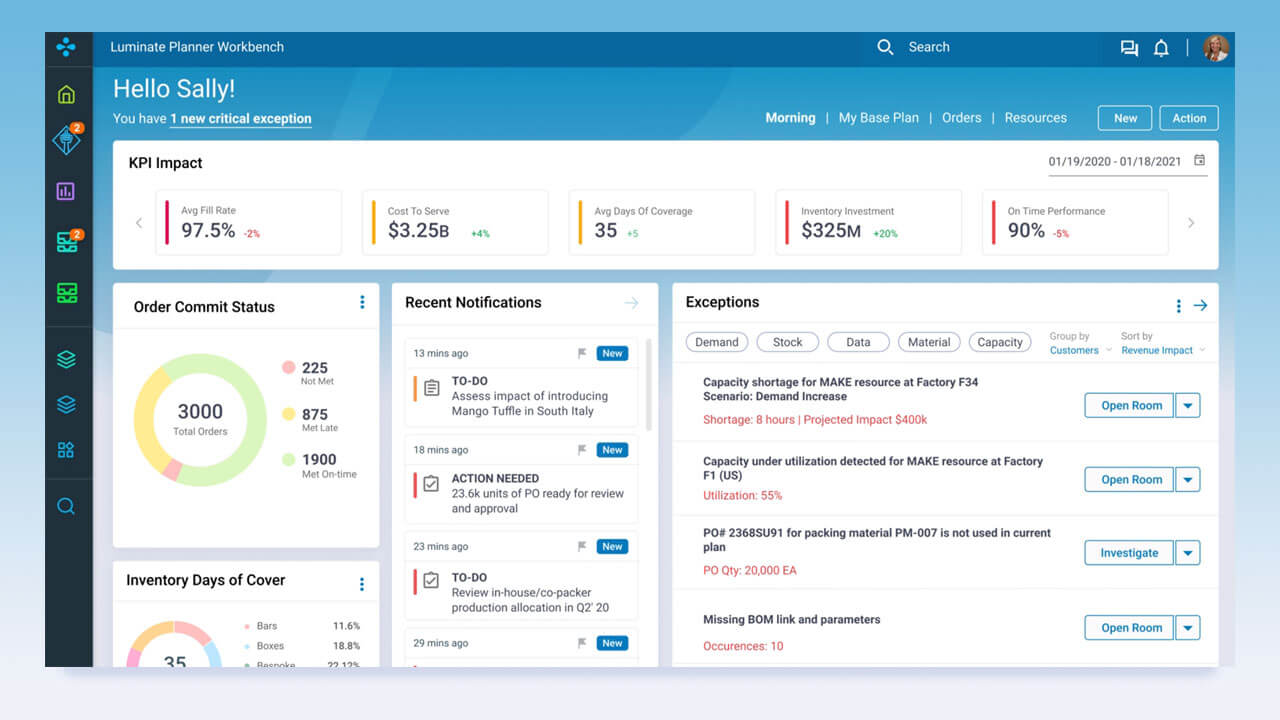

Gain supply chain agility with an optimized supply plan designed to meet volatile demand. An optimized plan can save your supply planner time, and help your organization minimize stock-outs and maximize inventory turns.

Supply Planning

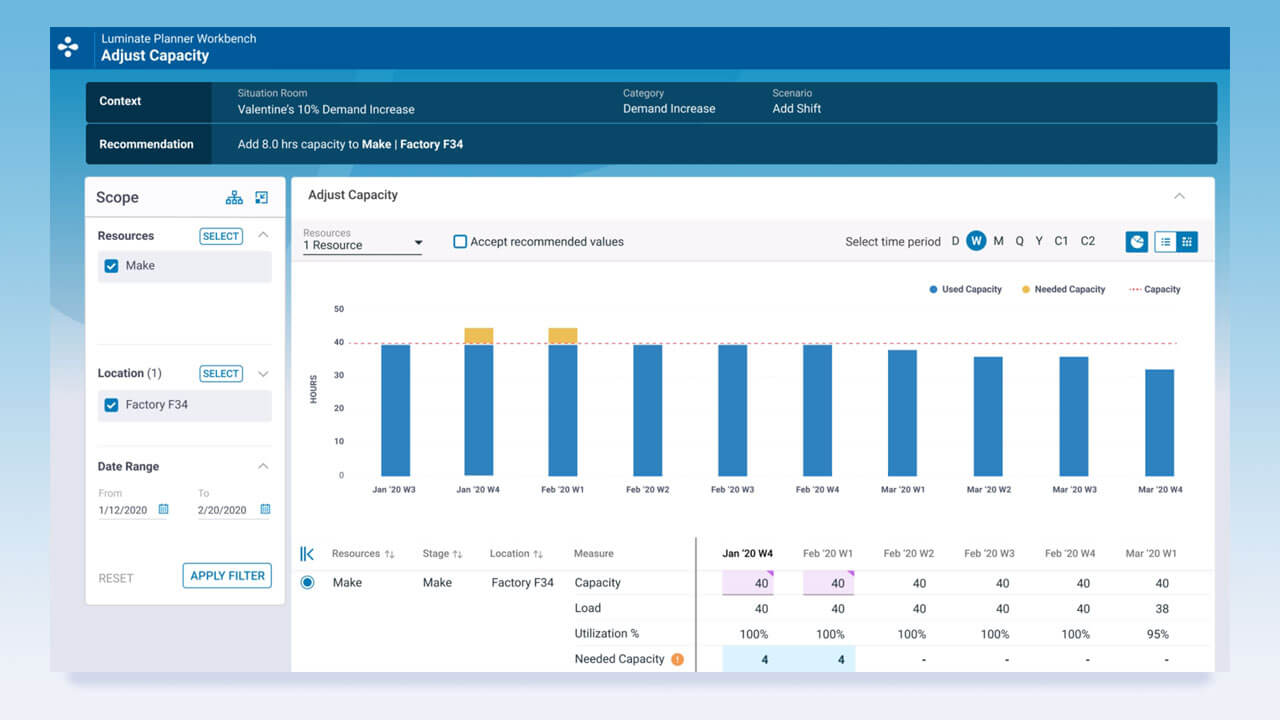

Scale from periodic to dynamic updating of the master plan by extending real time visibility across complex supply and delivery networks.

Stage the right inventory throughout your distribution network, minimizing stock-outs while maximizing inventory turns in your supply chain.

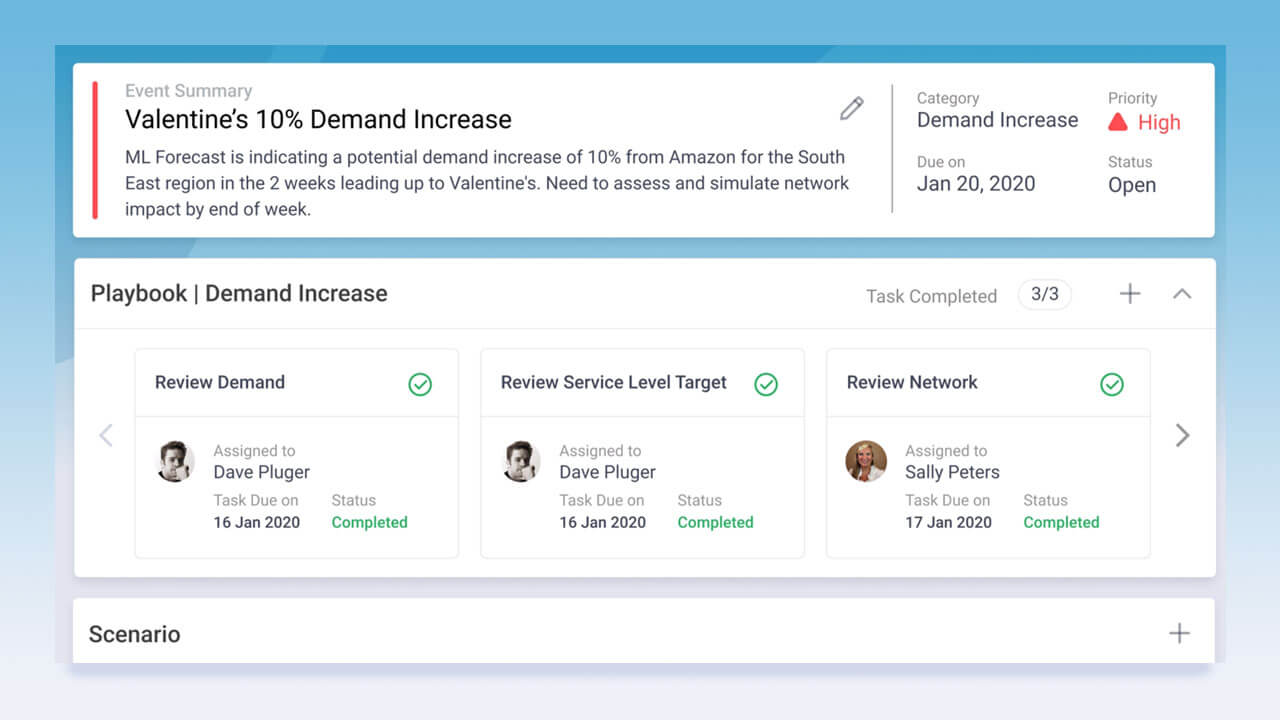

Experience real-time, collaborative scenario planning and communication between demand and supply planners.

Enable proactive systematic adjustments to ensure more consistent supply while reducing escalations, reducing cost and maximizing OTIF.

Empower planners to prepare for a range of future scenarios, including exception management workflows around managing safety-stock exceptions.

Fulfill Your Supply Planning Potential with Blue Yonder