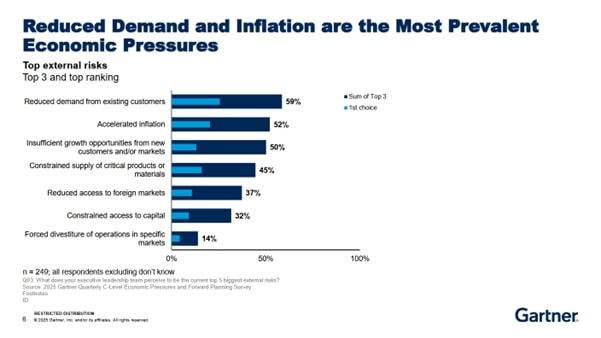

Supply chain leaders are facing pressure to reduce costs. All kinds of business are facing headwinds. “60% of executive team leaders do not perceive the environment to be favorable to company performance,” according to Gartner®, with reduced demand from existing customers and accelerated inflation their top two risks.

When asked in the Blue Yonder Supply Chain Compass survey about their biggest concerns, 28% of supply chain leaders explicitly mentioned rising costs, with retailers most likely to have this as their main concern (35%). It’s not surprising then that 63% of leaders surveyed said that managing supply chain costs is a key action for achieving their strategic goals this year.

However, many of the costs incurred in supply chains are structural and can be hard to change in the short or even medium term. That puts even greater pressure on the areas of supply chain management that can be optimized to become maximally efficient and cost-effective.

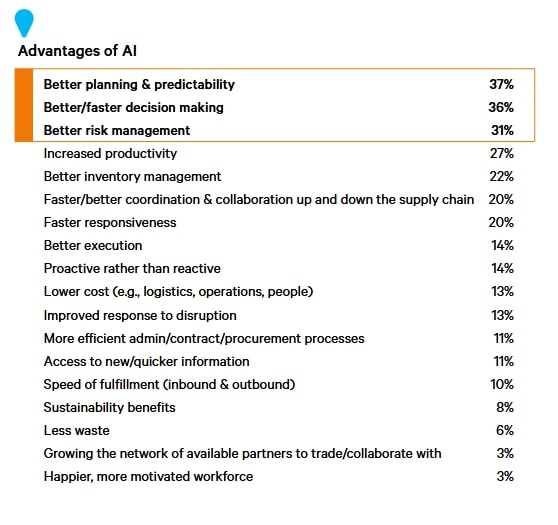

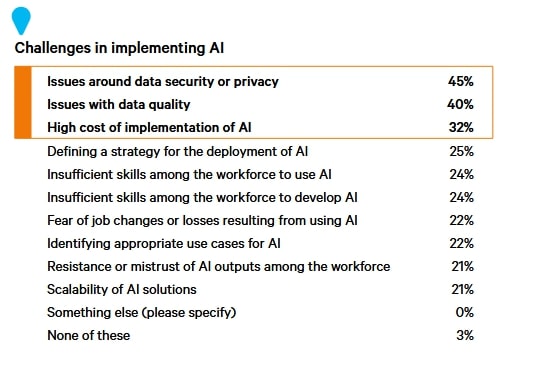

We know that AI is already changing how supply chains work, and that the scale, precision and speed at which AI can operate should drive efficiency and value across the end-to-end supply chain. So where do supply chain leaders see AI driving costs down, and what role does AI play in cost optimization strategies?

Priority differences

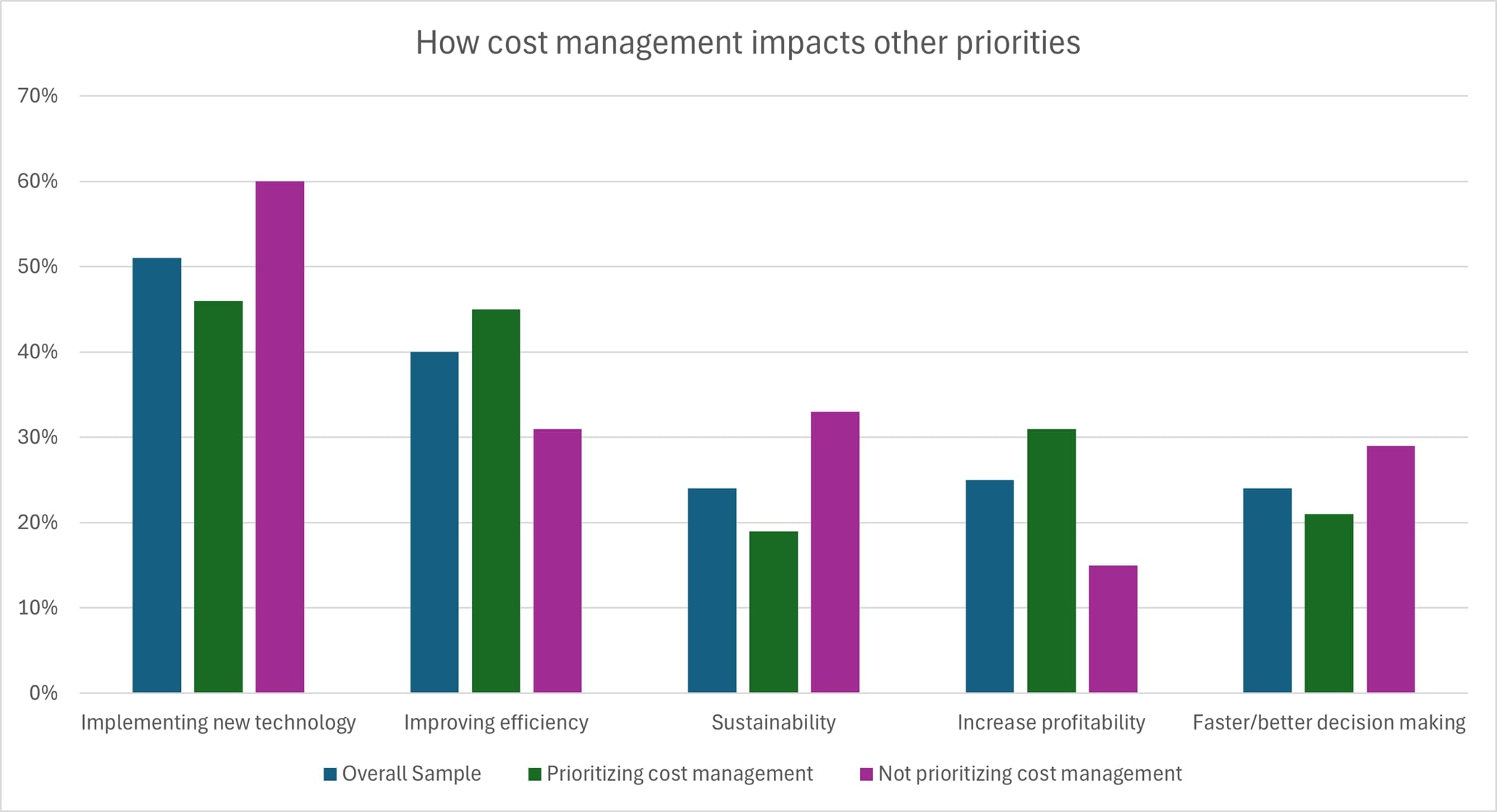

We can look at how strategic priorities differ between those leaders who told us that managing supply chain costs is a critical action and those who did not.

There’s an obvious logic to cost managers prioritizing profitability and efficiency more often than those who are less concerned with cost reduction. Implementing new technology can come with serious upfront costs, so it’s not surprising that this might be a lower priority for those managing costs. However, it seems at first glance that by deprioritizing new tech implementation, sustainability and faster/better decision making, leaders might fall into a trap.

The risk is that in an effort to keep costs lower in the short term, supply chain leaders don’t make the right investments to build intelligent, agile supply chains—those which can deliver long-term efficiency and profitability.

But that’s a risk these leaders seem very cognizant of. 83% agree that outdated technology will hold their supply chain back, and only 5% are confident in achieving their goals without upgrading their current technology stack.